Types of pumps

Apr 06, 2022|

Apr 06, 2022| View:328

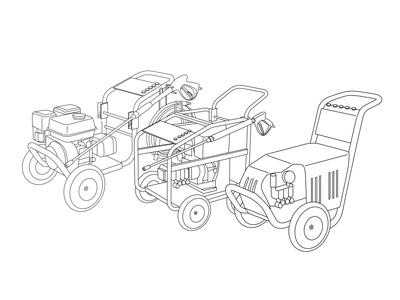

View:3281. According to the working principle and structure of the pump

2. According to the medium: clear water pump, sewage (dirt) pump, oil pump, corrosion resistant pump, fluorine lined pump, sewage pump, etc;

3. From the use of installation: pipeline pumps, submerged pumps, submersible pumps, etc.

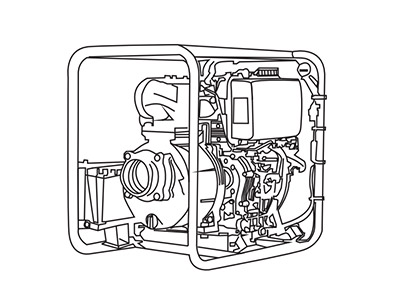

The working principle of centrifugal pump

Before the pump is started, the pump and the inlet pipe are filled with water. After the pump is running, under the action of centrifugal force generated by the impeller rotating at high speed, the water in the impeller runner is thrown around and pressed into the snail casing, the impeller inlet forms a vacuum, and the water in the pool is sucked along the suction pipe under the external atmospheric pressure to replenish the space. Then the inhaled water is thrown out by the impeller through the worm and into the discharge pipe. Centrifugal pumps are called centrifugal pumps because water is lifted to a high level under the action of centrifugal force generated by the high-speed rotation of the impeller.

|  |

Pump selection conditions

1. The physical and chemical properties of the conveyed medium

The physical and chemical properties of the transport medium directly affect the performance, material and structure of the pump, which is an important factor to be considered when selecting the model. Media name, media characteristics (corrosive, abrasive, toxic, etc.):, solid particle content and particle size, density, viscosity, vaporization pressure, gas content, whether crystallization, etc.

2. Process parameters (important basis for selection)

Flow Q:process device production, the amount of media required to be transported by the pump, the process personnel should generally give Normal, minimum and maximum flow rate should be given.

Pump data sheet is often given only the normal and rated flow rate of the pump. When selecting a pump, the rated flow is required, the Inlet pressure Ps and outlet pressure Pd: into, refers to the pump in and out of the pressure at the receiver flange, in and out The size of the outlet pressure affects the pressure resistance of the shell and shaft seal requirements.

Temperature T: pump inlet medium temperature, generally should give the process pump inlet medium normal, the minimum and maximum temperature of the pump inlet medium during the process.

Device cavitation margin NPSHa: effective cavitation margin.

Operation state: The operation state is divided into two kinds of continuous operation and intermittent operation.